What is the Common Production Process of Chip Resistors?

I. Introduction

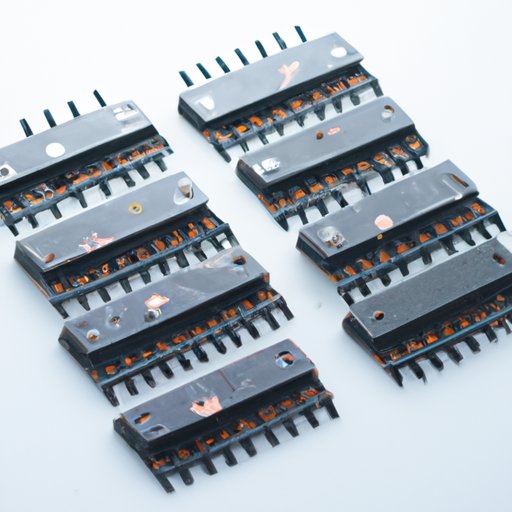

Chip resistors are essential components in modern electronic circuits, playing a critical role in controlling current flow and voltage levels. These tiny devices, often measuring just a few millimeters in size, are ubiquitous in everything from smartphones to automotive systems. Their compact size, reliability, and precision make them indispensable in the design of electronic devices. This blog post will explore the common production process of chip resistors, detailing the various types, raw materials, fabrication techniques, quality control measures, and future trends in the industry.

II. Types of Chip Resistors

Chip resistors can be broadly categorized into two main types: thin-film and thick-film resistors. Each type has distinct characteristics and applications.

A. Thin-Film Resistors

Thin-film resistors are made by depositing a very thin layer of resistive material onto a substrate.

1. **Characteristics**: These resistors offer high precision, low noise, and excellent temperature stability. They typically have a tolerance of ±1% or better, making them suitable for applications requiring high accuracy.

2. **Applications**: Thin-film resistors are commonly used in precision measurement devices, medical equipment, and high-frequency applications due to their stability and reliability.

B. Thick-Film Resistors

Thick-film resistors, on the other hand, are produced by screen printing a paste containing conductive materials onto a substrate.

1. **Characteristics**: These resistors are generally less expensive to produce than thin-film resistors and can handle higher power levels. However, they typically have a wider tolerance range, often around ±5% to ±10%.

2. **Applications**: Thick-film resistors are widely used in consumer electronics, automotive applications, and general-purpose circuits where cost-effectiveness is a priority.

C. Comparison between Thin-Film and Thick-Film Resistors

While both types of resistors serve similar functions, the choice between thin-film and thick-film resistors often depends on the specific requirements of the application, including precision, cost, and power handling capabilities.

III. Raw Materials

The production of chip resistors involves several key raw materials, each contributing to the performance and reliability of the final product.

A. Conductive Materials

1. **Metal Films for Thin-Film Resistors**: Common materials include nickel, chromium, and gold, which are deposited in thin layers to create the resistive element.

2. **Conductive Pastes for Thick-Film Resistors**: These pastes typically consist of a mixture of metal oxides and glass frit, which are printed onto the substrate and then fired to create a solid resistive layer.

B. Substrates

1. **Ceramic Substrates**: The most common substrate material for both thin-film and thick-film resistors, ceramics provide excellent thermal stability and electrical insulation.

2. **Other Materials**: In some cases, substrates made from glass or polymer materials may be used, particularly in specialized applications where flexibility or weight is a concern.

C. Protective Coatings

To enhance durability and performance, chip resistors are often coated with protective materials that shield them from environmental factors such as moisture and dust.

IV. Production Process Overview

The production of chip resistors involves several key steps, from design and prototyping to fabrication and quality control.

A. Design and Prototyping

1. **Circuit Design Considerations**: Engineers must consider factors such as resistance value, tolerance, and temperature coefficient when designing chip resistors for specific applications.

2. **Prototyping Methods**: Rapid prototyping techniques, such as 3D printing and computer-aided design (CAD), are often employed to create initial models for testing and validation.

B. Fabrication Techniques

The fabrication process varies significantly between thin-film and thick-film resistors.

1. **Thin-Film Resistor Fabrication**:

- **Sputtering**: A physical vapor deposition technique where target materials are bombarded with ions, causing atoms to be ejected and deposited onto the substrate.

- **Photolithography**: A process that uses light to transfer a geometric pattern from a photomask to a light-sensitive chemical photoresist on the substrate.

- **Etching**: A technique used to remove unwanted material, creating the desired resistor pattern.

2. **Thick-Film Resistor Fabrication**:

- **Screen Printing**: A method where a stencil is used to apply the conductive paste onto the substrate in the desired pattern.

- **Firing Process**: After printing, the substrate is heated in a furnace to cure the paste, forming a solid resistive layer.

C. Trimming and Tolerance Adjustment

Once the resistors are fabricated, they often require trimming to achieve the desired resistance value.

1. **Laser Trimming**: A precise method that uses a laser to remove material from the resistor, allowing for fine adjustments to the resistance value.

2. **Mechanical Trimming**: A less common method that involves physically cutting the resistor to achieve the desired resistance.

V. Quality Control Measures

Ensuring the quality and reliability of chip resistors is critical, and manufacturers implement several quality control measures throughout the production process.

A. Testing and Inspection

1. **Electrical Testing**: Each batch of resistors undergoes electrical testing to verify resistance values, tolerance, and performance under various conditions.

2. **Visual Inspection**: Automated and manual inspections are conducted to identify defects in the physical appearance of the resistors.

B. Reliability Testing

1. **Temperature Cycling**: Resistors are subjected to extreme temperature variations to assess their performance and reliability under thermal stress.

2. **Humidity Testing**: This testing evaluates how well resistors can withstand high humidity environments, which is crucial for applications in varying climates.

C. Compliance with Standards

1. **Industry Standards**: Manufacturers must adhere to various industry standards, such as ISO and IEC, which dictate quality and safety requirements.

2. **Certification Processes**: Many manufacturers seek certification from recognized organizations to demonstrate compliance with these standards, enhancing their credibility in the market.

VI. Packaging and Finalization

Once the chip resistors have passed quality control, they are prepared for packaging and distribution.

A. Packaging Methods

1. **Tape and Reel**: A common packaging method for surface-mount devices, where resistors are placed in a continuous strip of tape and wound onto a reel for easy handling and automated assembly.

2. **Bulk Packaging**: For applications where resistors are manually placed, bulk packaging may be used, allowing for easier access to individual components.

B. Labeling and Documentation

Proper labeling and documentation are essential for tracking and quality assurance, providing information such as part numbers, specifications, and manufacturing dates.

C. Shipping and Distribution

Once packaged, chip resistors are shipped to distributors and manufacturers, ready to be integrated into electronic devices.

VII. Future Trends in Chip Resistor Production

The chip resistor industry is evolving, driven by advances in technology and changing market demands.

A. Advances in Materials Science

Research into new materials, such as nanomaterials and advanced ceramics, is paving the way for the development of resistors with improved performance characteristics.

B. Automation and Industry 4.0

The integration of automation and smart manufacturing technologies is streamlining production processes, enhancing efficiency, and reducing costs.

C. Environmental Considerations and Sustainability

As the electronics industry faces increasing pressure to adopt sustainable practices, manufacturers are exploring eco-friendly materials and production methods to minimize their environmental impact.

VIII. Conclusion

In summary, the production process of chip resistors is a complex and multifaceted endeavor that involves careful consideration of materials, fabrication techniques, and quality control measures. As technology continues to advance, the importance of innovation and quality in the chip resistor industry will only grow. With ongoing research and development, the future of chip resistors looks promising, ensuring their continued relevance in the ever-evolving world of electronics.