How big is the market size for resistor pictures?

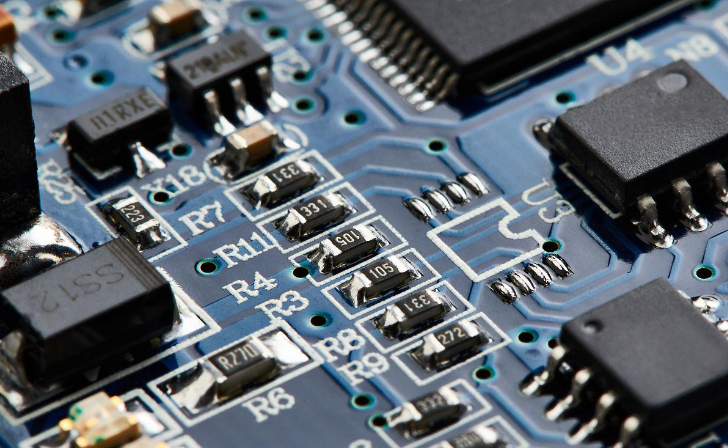

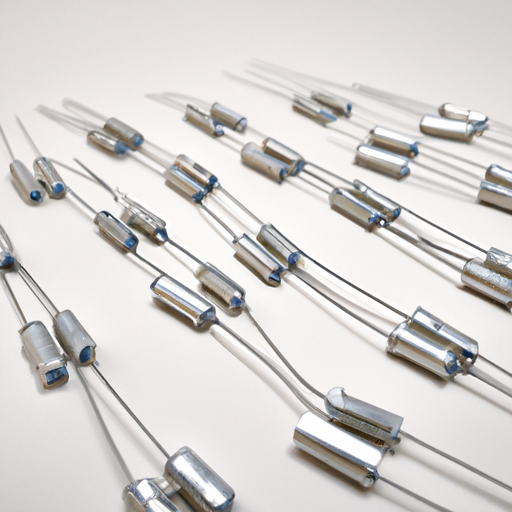

Resistor Market Size Analysis IntroductionA resistor is one of the most basic components in electronic circuits, its main function is to limit the flow of current, protecting the circuit's safety and stability. Resistors play a crucial role in various electronic devices, from simple household appliances to complex industrial equipment, they are almost everywhere. With the continuous advancement of technology and the continuous growth of electronic product demand, the market size of resistors is also expanding. Therefore, studying the market size of resistors is not only to understand the current market situation, but also to grasp future development trends and provide decision-making basis for industry participants. Resistor Market Overview Basic Situation of Global Resistor MarketAccording to market research institutions, the global resistor market has shown a steady growth trend in recent years. It is expected that by 2025, the market size will reach billions of dollars. The growth of the resistor market is mainly driven by the increasing demand for electronic products and the development of emerging technologies. Market SegmentationThe resistor market can be classified according to different criteria:1. **By Type**: Resistors are mainly divided into fixed resistors, variable resistors, and special resistors, etc.2. **By Application Area**: Resistors are widely used in consumer electronics, automotive electronics, industrial automation, communication equipment, and other fields.3. **By Region**: The market can be divided into North America, Europe, Asia-Pacific, and other regions. Major Resistor Manufacturers and Market ShareIn the global resistor market, major manufacturers include Murata Manufacturing, Rohm Semiconductor, TE Connectivity, Vishay Intertechnology, etc. These companies occupy a large market share due to their technological advantages and market experience. Current Status of Resistor Market Size Statistical Data on Current Market SizeAccording to the latest market research report, the global resistor market size is approximately XX billion dollars in 2023, and is expected to continue to expand at an annual growth rate of X% in the coming years. Major Market Drivers1. **Growth in Demand for Electronic Products**: With the popularity of smartphones, tablets, wearable devices, and other consumer electronics products, the demand for resistors is also increasing.2. **Driving Force of Emerging Technologies**: The development of emerging technologies such as 5G, IoT, and AI is driving the demand for high-performance resistors. Market Challenges and Limiting Factors1. **Fluctuation in Raw Material Prices**: The production of resistors depends on a variety of raw materials, and fluctuations in raw material prices may affect production costs.2. **Intensified Competition**: With the expansion of the market, an increasing number of companies are entering the resistor market, leading to intensified competition. Future Trends of Resistor Market Expected Market Growth Rate and Future Size ForecastAccording to market analysis, it is expected that by 2030, the resistor market size will reach XX billion dollars, and the annual growth rate will remain around X%. Impact of New Technologies on the Market1. **Increase in Demand for High-Precision Resistors**: With the increasing performance requirements of electronic devices, the demand for high-precision resistors will significantly increase.2. **Rise of Environmentally Friendly Resistors**: The enhancement of environmental awareness is prompting manufacturers to develop more environmentally friendly resistor products to meet market demand. Potential in Market Segmentation Areas1. **Automotive Electronics**: With the rise of electric vehicles and smart cars, the demand for resistors in the automotive electronics market will significantly increase.2. **Consumer Electronics**: The popularity of emerging consumer electronics products such as smart homes and wearable devices will further drive the growth of the resistor market.3. **Industrial Automation**: The advancement of Industry 4.0 is leading to a continuous increase in the demand for resistors in industrial automation equipment. Regional Market Analysis North America MarketThe North America market is an important part of the global resistor market, with a large market size and great growth potential. Major companies such as Murata, Vishay, etc., hold a large market share in this region. Europe MarketThe European market is a leader in resistor technology innovation, with characteristics including strong demand for high-end products and the rise of environmentally friendly products. Asia-Pacific MarketThe Asia-Pacific region is the fastest-growing region in the resistor market, mainly due to the rapid development of the electronics manufacturing industry and the increasing demand for consumer electronics products. Countries such as China, Japan, and South Korea have performed particularly well in the market. Other Regions MarketThe resistor market in regions such as Latin America, the Middle East, and Africa, although relatively small, will also show some growth potential in the future with economic development and increasing demand for electronic products. ConclusionThe overall assessment of the resistor market size shows that the market is in a rapid growth stage with broad prospects for future development. Industry participants should pay attention to market dynamics, seize opportunities brought by emerging technologies, and also address challenges such as fluctuation in raw material prices and intensified competition. Future research directions should focus on the development of new materials, promotion of environmentally friendly products, and in-depth exploration of market segmentation areas. References1. Market research reports2. Statistics from industry associations and organizations3. Academic papers and professional books Closing RemarksThe importance of the resistor market is self-evident, and its development prospects are promising. With the continuous advancement of technology and the changing market demand, the resistor industry will usher in new opportunities and challenges. It is hoped that participants inside and outside the industry can pay attention to this market, actively invest and innovate, and jointly promote the sustainable development of the resistor market. Resistor Market Size Analysis IntroductionA resistor is one of the most basic components in electronic circuits, its main function is to limit the flow of current, protecting the circuit's safety and stability. Resistors play a crucial role in various electronic devices, from simple household appliances to complex industrial equipment, they are almost everywhere. With the continuous advancement of technology and the continuous growth of electronic product demand, the market size of resistors is also expanding. Therefore, studying the market size of resistors is not only to understand the current market situation, but also to grasp future development trends and provide decision-making basis for industry participants. Resistor Market Overview Basic Situation of Global Resistor MarketAccording to market research institutions, the global resistor market has shown a steady growth trend in recent years. It is expected that by 2025, the market size will reach billions of dollars. The growth of the resistor market is mainly driven by the increasing demand for electronic products and the development of emerging technologies. Market SegmentationThe resistor market can be classified according to different criteria:1. **By Type**: Resistors are mainly divided into fixed resistors, variable resistors, and special resistors, etc.2. **By Application Area**: Resistors are widely used in consumer electronics, automotive electronics, industrial automation, communication equipment, and other fields.3. **By Region**: The market can be divided into North America, Europe, Asia-Pacific, and other regions. Major Resistor Manufacturers and Market ShareIn the global resistor market, major manufacturers include Murata Manufacturing, Rohm Semiconductor, TE Connectivity, Vishay Intertechnology, etc. These companies occupy a large market share due to their technological advantages and market experience. Current Status of Resistor Market Size Statistical Data on Current Market SizeAccording to the latest market research report, the global resistor market size is approximately XX billion dollars in 2023, and is expected to continue to expand at an annual growth rate of X% in the coming years. Major Market Drivers1. **Growth in Demand for Electronic Products**: With the popularity of smartphones, tablets, wearable devices, and other consumer electronics products, the demand for resistors is also increasing.2. **Driving Force of Emerging Technologies**: The development of emerging technologies such as 5G, IoT, and AI is driving the demand for high-performance resistors. Market Challenges and Limiting Factors1. **Fluctuation in Raw Material Prices**: The production of resistors depends on a variety of raw materials, and fluctuations in raw material prices may affect production costs.2. **Intensified Competition**: With the expansion of the market, an increasing number of companies are entering the resistor market, leading to intensified competition. Future Trends of Resistor Market Expected Market Growth Rate and Future Size ForecastAccording to market analysis, it is expected that by 2030, the resistor market size will reach XX billion dollars, and the annual growth rate will remain around X%. Impact of New Technologies on the Market1. **Increase in Demand for High-Precision Resistors**: With the increasing performance requirements of electronic devices, the demand for high-precision resistors will significantly increase.2. **Rise of Environmentally Friendly Resistors**: The enhancement of environmental awareness is prompting manufacturers to develop more environmentally friendly resistor products to meet market demand. Potential in Market Segmentation Areas1. **Automotive Electronics**: With the rise of electric vehicles and smart cars, the demand for resistors in the automotive electronics market will significantly increase.2. **Consumer Electronics**: The popularity of emerging consumer electronics products such as smart homes and wearable devices will further drive the growth of the resistor market.3. **Industrial Automation**: The advancement of Industry 4.0 is leading to a continuous increase in the demand for resistors in industrial automation equipment. Regional Market Analysis North America MarketThe North America market is an important part of the global resistor market, with a large market size and great growth potential. Major companies such as Murata, Vishay, etc., hold a large market share in this region. Europe MarketThe European market is a leader in resistor technology innovation, with characteristics including strong demand for high-end products and the rise of environmentally friendly products. Asia-Pacific MarketThe Asia-Pacific region is the fastest-growing region in the resistor market, mainly due to the rapid development of the electronics manufacturing industry and the increasing demand for consumer electronics products. Countries such as China, Japan, and South Korea have performed particularly well in the market. Other Regions MarketThe resistor market in regions such as Latin America, the Middle East, and Africa, although relatively small, will also show some growth potential in the future with economic development and increasing demand for electronic products. ConclusionThe overall assessment of the resistor market size shows that the market is in a rapid growth stage with broad prospects for future development. Industry participants should pay attention to market dynamics, seize opportunities brought by emerging technologies, and also address challenges such as fluctuation in raw material prices and intensified competition. Future research directions should focus on the development of new materials, promotion of environmentally friendly products, and in-depth exploration of market segmentation areas. References1. Market research reports2. Statistics from industry associations and organizations3. Academic papers and professional books Closing RemarksThe importance of the resistor market is self-evident, and its development prospects are promising. With the continuous advancement of technology and the changing market demand, the resistor industry will usher in new opportunities and challenges. It is hoped that participants inside and outside the industry can pay attention to this market, actively invest and innovate, and jointly promote the sustainable development of the resistor market. Resistor Market Size Analysis IntroductionA resistor is one of the most basic components in electronic circuits, its main function is to limit the flow of current, protecting the circuit's safety and stability. Resistors play a crucial role in various electronic devices, from simple household appliances to complex industrial equipment, they are almost everywhere. With the continuous advancement of technology and the continuous growth of electronic product demand, the market size of resistors is also expanding. Therefore, studying the market size of resistors is not only to understand the current market situation, but also to grasp future development trends and provide decision-making basis for industry participants. Resistor Market Overview Basic Situation of Global Resistor MarketAccording to market research institutions, the global resistor market has shown a steady growth trend in recent years. It is expected that by 2025, the market size will reach billions of dollars. The growth of the resistor market is mainly driven by the increasing demand for electronic products and the development of emerging technologies. Market SegmentationThe resistor market can be classified according to different criteria:1. **By Type**: Resistors are mainly divided into fixed resistors, variable resistors, and special resistors, etc.2. **By Application Area**: Resistors are widely used in consumer electronics, automotive electronics, industrial automation, communication equipment, and other fields.3. **By Region**: The market can be divided into North America, Europe, Asia-Pacific, and other regions. Major Resistor Manufacturers and Market ShareIn the global resistor market, major manufacturers include Murata Manufacturing, Rohm Semiconductor, TE Connectivity, Vishay Intertechnology, etc. These companies occupy a large market share due to their technological advantages and market experience. Current Status of Resistor Market Size Statistical Data on Current Market SizeAccording to the latest market research report, the global resistor market size is approximately XX billion dollars in 2023, and is expected to continue to expand at an annual growth rate of X% in the coming years. Major Market Drivers1. **Growth in Demand for Electronic Products**: With the popularity of smartphones, tablets, wearable devices, and other consumer electronics products, the demand for resistors is also increasing.2. **Driving Force of Emerging Technologies**: The development of emerging technologies such as 5G, IoT, and AI is driving the demand for high-performance resistors. Market Challenges and Limiting Factors1. **Fluctuation in Raw Material Prices**: The production of resistors depends on a variety of raw materials, and fluctuations in raw material prices may affect production costs.2. **Intensified Competition**: With the expansion of the market, an increasing number of companies are entering the resistor market, leading to intensified competition. Future Trends of Resistor Market Expected Market Growth Rate and Future Size ForecastAccording to market analysis, it is expected that by 2030, the resistor market size will reach XX billion dollars, and the annual growth rate will remain around X%. Impact of New Technologies on the Market1. **Increase in Demand for High-Precision Resistors**: With the increasing performance requirements of electronic devices, the demand for high-precision resistors will significantly increase.2. **Rise of Environmentally Friendly Resistors**: The enhancement of environmental awareness is prompting manufacturers to develop more environmentally friendly resistor products to meet market demand. Potential in Market Segmentation Areas1. **Automotive Electronics**: With the rise of electric vehicles and smart cars, the demand for resistors in the automotive electronics market will significantly increase.2. **Consumer Electronics**: The popularity of emerging consumer electronics products such as smart homes and wearable devices will further drive the growth of the resistor market.3. **Industrial Automation**: The advancement of Industry 4.0 is leading to a continuous increase in the demand for resistors in industrial automation equipment. Regional Market Analysis North America MarketThe North America market is an important part of the global resistor market, with a large market size and great growth potential. Major companies such as Murata, Vishay, etc., hold a large market share in this region. Europe MarketThe European market is a leader in resistor technology innovation, with characteristics including strong demand for high-end products and the rise of environmentally friendly products. Asia-Pacific MarketThe Asia-Pacific region is the fastest-growing region in the resistor market, mainly due to the rapid development of the electronics manufacturing industry and the increasing demand for consumer electronics products. Countries such as China, Japan, and South Korea have performed particularly well in the market. Other Regions MarketThe resistor market in regions such as Latin America, the Middle East, and Africa, although relatively small, will also show some growth potential in the future with economic development and increasing demand for electronic products. ConclusionThe overall assessment of the resistor market size shows that the market is in a rapid growth stage with broad prospects for future development. Industry participants should pay attention to market dynamics, seize opportunities brought by emerging technologies, and also address challenges such as fluctuation in raw material prices and intensified competition. Future research directions should focus on the development of new materials, promotion of environmentally friendly products, and in-depth exploration of market segmentation areas. References1. Market research reports2. Statistics from industry associations and organizations3. Academic papers and professional books Closing RemarksThe importance of the resistor market is self-evident, and its development prospects are promising. With the continuous advancement of technology and the changing market demand, the resistor industry will usher in new opportunities and challenges. It is hoped that participants inside and outside the industry can pay attention to this market, actively invest and innovate, and jointly promote the sustainable development of the resistor market. Resistor Market Size Analysis IntroductionA resistor is one of the most basic components in electronic circuits, its main function is to limit the flow of current, protecting the circuit's safety and stability. Resistors play a crucial role in various electronic devices, from simple household appliances to complex industrial equipment, they are almost everywhere. With the continuous advancement of technology and the continuous growth of electronic product demand, the market size of resistors is also expanding. Therefore, studying the market size of resistors is not only to understand the current market situation, but also to grasp future development trends and provide decision-making basis for industry participants. Resistor Market Overview Basic Situation of Global Resistor MarketAccording to market research institutions, the global resistor market has shown a steady growth trend in recent years. It is expected that by 2025, the market size will reach billions of dollars. The growth of the resistor market is mainly driven by the increasing demand for electronic products and the development of emerging technologies. Market SegmentationThe resistor market can be classified according to different criteria:1. **By Type**: Resistors are mainly divided into fixed resistors, variable resistors, and special resistors, etc.2. **By Application Area**: Resistors are widely used in consumer electronics, automotive electronics, industrial automation, communication equipment, and other fields.3. **By Region**: The market can be divided into North America, Europe, Asia-Pacific, and other regions. Major Resistor Manufacturers and Market ShareIn the global resistor market, major manufacturers include Murata Manufacturing, Rohm Semiconductor, TE Connectivity, Vishay Intertechnology, etc. These companies occupy a large market share due to their technological advantages and market experience. Current Status of Resistor Market Size Statistical Data on Current Market SizeAccording to the latest market research report, the global resistor market size is approximately XX billion dollars in 2023, and is expected to continue to expand at an annual growth rate of X% in the coming years. Major Market Drivers1. **Growth in Demand for Electronic Products**: With the popularity of smartphones, tablets, wearable devices, and other consumer electronics products, the demand for resistors is also increasing.2. **Driving Force of Emerging Technologies**: The development of emerging technologies such as 5G, IoT, and AI is driving the demand for high-performance resistors. Market Challenges and Limiting Factors1. **Fluctuation in Raw Material Prices**: The production of resistors depends on a variety of raw materials, and fluctuations in raw material prices may affect production costs.2. **Intensified Competition**: With the expansion of the market, an increasing number of companies are entering the resistor market, leading to intensified competition. Future Trends of Resistor Market Expected Market Growth Rate and Future Size ForecastAccording to market analysis, it is expected that by 2030, the resistor market size will reach XX billion dollars, and the annual growth rate will remain around X%. Impact of New Technologies on the Market1. **Increase in Demand for High-Precision Resistors**: With the increasing performance requirements of electronic devices, the demand for high-precision resistors will significantly increase.2. **Rise of Environmentally Friendly Resistors**: The enhancement of environmental awareness is prompting manufacturers to develop more environmentally friendly resistor products to meet market demand. Potential in Market Segmentation Areas1. **Automotive Electronics**: With the rise of electric vehicles and smart cars, the demand for resistors in the automotive electronics market will significantly increase.2. **Consumer Electronics**: The popularity of emerging consumer electronics products such as smart homes and wearable devices will further drive the growth of the resistor market.3. **Industrial Automation**: The advancement of Industry 4.0 is leading to a continuous increase in the demand for resistors in industrial automation equipment. Regional Market Analysis North America MarketThe North America market is an important part of the global resistor market, with a large market size and great growth potential. Major companies such as Murata, Vishay, etc., hold a large market share in this region. Europe MarketThe European market is a leader in resistor technology innovation, with characteristics including strong demand for high-end products and the rise of environmentally friendly products. Asia-Pacific MarketThe Asia-Pacific region is the fastest-growing region in the resistor market, mainly due to the rapid development of the electronics manufacturing industry and the increasing demand for consumer electronics products. Countries such as China, Japan, and South Korea have performed particularly well in the market. Other Regions MarketThe resistor market in regions such as Latin America, the Middle East, and Africa, although relatively small, will also show some growth potential in the future with economic development and increasing demand for electronic products. ConclusionThe overall assessment of the resistor market size shows that the market is in a rapid growth stage with broad prospects for future development. Industry participants should pay attention to market dynamics, seize opportunities brought by emerging technologies, and also address challenges such as fluctuation in raw material prices and intensified competition. Future research directions should focus on the development of new materials, promotion of environmentally friendly products, and in-depth exploration of market segmentation areas. References1. Market research reports2. Statistics from industry associations and organizations3. Academic papers and professional books Closing RemarksThe importance of the resistor market is self-evident, and its development prospects are promising. With the continuous advancement of technology and the changing market demand, the resistor industry will usher in new opportunities and challenges. It is hoped that participants inside and outside the industry can pay attention to this market, actively invest and innovate, and jointly promote the sustainable development of the resistor market.

2025-01-18