The Latest Crane Resistor Wiring Diagram Specification Sheet

I. Introduction

Crane operations are critical in various industries, from construction to manufacturing, where heavy lifting and precise movements are essential. At the heart of these operations lies the crane resistor, a vital component that ensures the safe and efficient functioning of cranes. This blog post aims to provide a comprehensive overview of the latest crane resistor wiring diagram specification sheet, highlighting the importance of proper wiring and adherence to specifications in enhancing operational safety and efficiency.

Wiring diagrams serve as essential tools in electrical systems, providing a visual representation of how components are interconnected. They are crucial for understanding the layout and functionality of electrical systems, especially in complex machinery like cranes. This specification sheet will delve into the intricacies of crane resistors, their wiring diagrams, and best practices for installation and maintenance.

II. Understanding Crane Resistors

A. Definition and Function of Crane Resistors

Crane resistors are electrical components that play a significant role in controlling motor speed and torque. They are designed to manage the flow of electrical current, ensuring that cranes operate smoothly and safely under varying load conditions. By regulating the amount of current that reaches the motor, crane resistors help prevent overheating and potential damage, thereby enhancing the longevity of the equipment.

1. **Role in Controlling Motor Speed and Torque**: Crane resistors allow operators to adjust the speed and torque of the crane's motor, providing better control during lifting and lowering operations. This is particularly important when handling delicate or heavy loads, as it minimizes the risk of accidents and equipment failure.

2. **Importance in Load Management and Safety**: Proper load management is crucial in crane operations. Crane resistors help distribute the load evenly, preventing sudden jerks or drops that could lead to accidents. They also play a role in dynamic braking, allowing the crane to stop safely and efficiently.

B. Types of Crane Resistors

There are several types of crane resistors, each serving a specific purpose in crane operations:

1. **Dynamic Braking Resistors**: These resistors are used to dissipate energy generated during braking, converting it into heat. This process helps slow down the crane smoothly and prevents damage to the motor.

2. **Starting Resistors**: Starting resistors are employed during the initial phase of motor operation. They limit the inrush current, allowing the motor to start gradually and reducing the risk of electrical surges.

3. **Load Resistors**: Load resistors are used to balance the electrical load in the system, ensuring that the crane operates efficiently under varying conditions.

III. Components of the Wiring Diagram

A. Key Symbols and Notations Used in Wiring Diagrams

Wiring diagrams utilize specific symbols and notations to represent various components and connections. Understanding these symbols is crucial for interpreting the diagrams accurately.

1. **Resistor Symbols**: Resistors are typically represented by a zigzag line or a rectangle, depending on the diagram's conventions.

2. **Connection Points**: Dots or small circles indicate connection points where wires or components are joined.

3. **Power Sources and Loads**: Power sources, such as batteries or transformers, are usually depicted with specific symbols, while loads are represented by rectangles or circles.

B. Explanation of Each Component in the Diagram

1. **Resistors**: The primary focus of the wiring diagram, resistors control the flow of current and manage motor performance.

2. **Switches**: Switches are used to control the flow of electricity, allowing operators to turn the system on or off as needed.

3. **Circuit Breakers**: These safety devices protect the electrical system from overloads and short circuits, automatically disconnecting the power when necessary.

4. **Connectors and Terminals**: Connectors and terminals facilitate the joining of wires and components, ensuring a secure and reliable electrical connection.

IV. The Latest Wiring Diagram Specifications

A. Overview of the Latest Standards and Regulations

Adhering to industry standards and regulations is essential for ensuring the safety and reliability of crane operations. The latest specifications are guided by organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI).

1. **Industry Standards (e.g., IEC, ANSI)**: These standards provide guidelines for the design, installation, and maintenance of electrical systems, including crane resistors.

2. **Safety Regulations**: Compliance with safety regulations is crucial to prevent accidents and ensure the well-being of operators and personnel.

B. Detailed Explanation of the Wiring Diagram Layout

1. **Typical Configurations for Different Crane Types**: Wiring diagrams may vary based on the type of crane (e.g., overhead, gantry, or mobile cranes). Understanding these configurations is essential for proper installation.

2. **Color Coding and Labeling Conventions**: Color coding is often used to differentiate between various wires and components, making it easier to follow the diagram. Labels should be clear and concise to avoid confusion during installation.

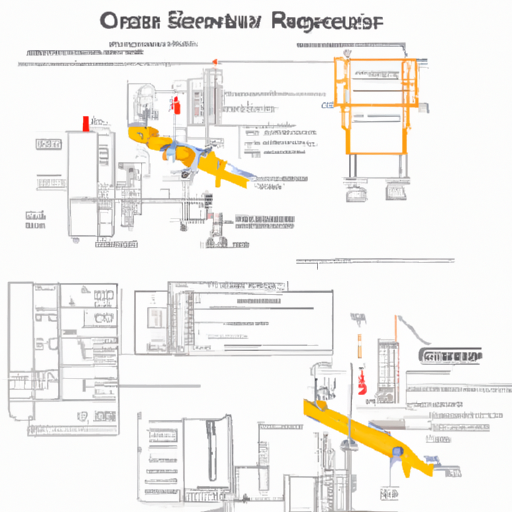

C. Example of a Typical Crane Resistor Wiring Diagram

An annotated diagram can provide a visual reference for understanding the components and connections involved in crane resistor wiring. Each part of the diagram should be clearly labeled, with explanations of its function and importance.

V. Installation Guidelines

A. Step-by-Step Instructions for Wiring Crane Resistors

Proper installation of crane resistors is crucial for ensuring safe and efficient operation. Here are some step-by-step instructions:

1. **Tools and Materials Needed**: Gather all necessary tools, including wire strippers, screwdrivers, and multimeters, as well as the required materials, such as wires, connectors, and resistors.

2. **Safety Precautions**: Always disconnect power before starting any electrical work. Use personal protective equipment (PPE) and follow safety protocols to prevent accidents.

B. Common Mistakes to Avoid During Installation

1. **Ignoring the Wiring Diagram**: Failing to follow the wiring diagram accurately can lead to incorrect connections and potential equipment failure.

2. **Overlooking Safety Regulations**: Neglecting safety regulations can result in hazardous situations, putting operators and equipment at risk.

C. Importance of Following the Wiring Diagram Accurately

Adhering to the wiring diagram is essential for ensuring that all components are connected correctly. This not only enhances the performance of the crane but also minimizes the risk of electrical faults and accidents.

VI. Maintenance and Troubleshooting

A. Regular Maintenance Practices for Crane Resistors

1. **Inspection Routines**: Regular inspections should be conducted to identify any signs of wear or damage to the resistors and wiring.

2. **Cleaning and Testing Procedures**: Keeping the components clean and performing routine tests can help ensure optimal performance and longevity.

B. Troubleshooting Common Issues

1. **Identifying Wiring Faults**: Common wiring faults include loose connections, damaged wires, and incorrect configurations. Using a multimeter can help diagnose these issues.

2. **Diagnosing Resistor Failures**: Resistor failures can manifest as overheating or inconsistent performance. Testing the resistors with appropriate equipment can help identify the problem.

3. **Recommended Solutions**: Depending on the issue, solutions may include tightening connections, replacing damaged components, or recalibrating the system.

VII. Conclusion

In conclusion, understanding the latest crane resistor wiring diagram specification sheet is essential for ensuring safe and efficient crane operations. Proper wiring and adherence to specifications not only enhance the performance of the equipment but also play a crucial role in operational safety. We encourage operators and technicians to refer to the latest specification sheet for best practices and to stay informed about industry standards and regulations.

Crane resistors are integral to the safe and efficient functioning of cranes, and their proper installation and maintenance are vital for enhancing operational safety and efficiency. By following the guidelines outlined in this blog post, operators can ensure that their crane systems remain reliable and effective.

VIII. References

1. International Electrotechnical Commission (IEC) Standards

2. American National Standards Institute (ANSI) Guidelines

3. Manufacturer Manuals and Technical Specifications

4. Industry Publications on Crane Operations and Safety

For further understanding of crane resistors and wiring diagrams, we recommend consulting industry experts or contacting manufacturers for additional support.