The Production Process of Mainstream Resistor Wiring Diagrams

I. Introduction

Resistors are fundamental components in electronic circuits, serving to limit current flow, divide voltages, and dissipate energy. Their importance cannot be overstated, as they play a crucial role in ensuring that electronic devices function correctly and safely. To effectively utilize resistors in circuit design, engineers rely on resistor wiring diagrams, which provide a visual representation of how resistors are integrated into a circuit. This blog post will explore the production process of mainstream resistor wiring diagrams, detailing each step from initial design to final documentation.

II. Understanding Resistors

A. Types of Resistors

Resistors come in various types, each serving specific functions within electronic circuits:

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in circuits where a specific resistance is required.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow for adjustable resistance, making them ideal for applications like volume controls in audio equipment.

3. **Specialty Resistors**: This category includes thermistors, photoresistors, and other specialized components designed for specific applications, such as temperature sensing or light detection.

B. Key Specifications

When selecting resistors for a circuit, several key specifications must be considered:

1. **Resistance Value**: Measured in ohms (Ω), this value determines how much the resistor opposes the flow of current.

2. **Tolerance**: This specification indicates the accuracy of the resistor's resistance value, expressed as a percentage. A lower tolerance means a more precise resistor.

3. **Power Rating**: Measured in watts (W), this rating indicates the maximum power the resistor can dissipate without overheating.

C. Applications of Resistors in Circuits

Resistors are used in a wide range of applications, including voltage dividers, current limiters, pull-up and pull-down configurations, and as part of filter circuits. Their versatility makes them essential in both analog and digital electronics.

III. The Role of Wiring Diagrams

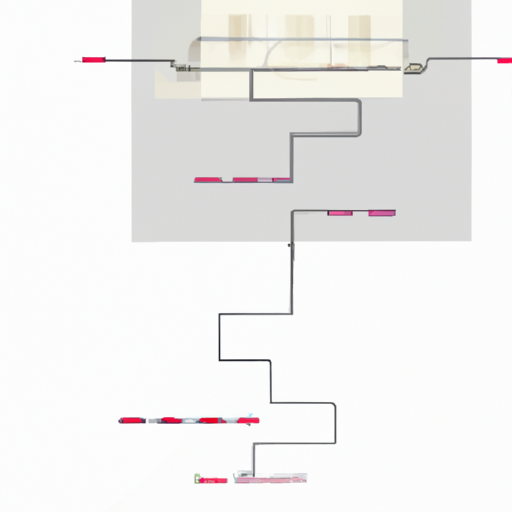

A. Definition and Purpose of Wiring Diagrams

Wiring diagrams are visual representations of electrical circuits, illustrating how components are connected and how current flows through the system. They serve as essential tools for engineers and technicians, providing clarity and guidance during the design, assembly, and troubleshooting phases of circuit development.

B. Components of a Wiring Diagram

1. **Symbols and Notations**: Wiring diagrams use standardized symbols to represent various components, including resistors, capacitors, and power sources. Understanding these symbols is crucial for interpreting the diagrams accurately.

2. **Layout and Design**: The layout of a wiring diagram must be clear and logical, allowing users to follow the connections easily. Good design practices enhance readability and reduce the likelihood of errors.

C. Importance in Circuit Design and Troubleshooting

Accurate wiring diagrams are vital for successful circuit design and troubleshooting. They help engineers visualize the circuit, identify potential issues, and ensure that components are connected correctly. In the event of a malfunction, a well-documented wiring diagram can significantly expedite the troubleshooting process.

IV. The Production Process of Resistor Wiring Diagrams

A. Initial Design Phase

The production of resistor wiring diagrams begins with the initial design phase, where engineers conceptualize the circuit design. This phase involves:

1. **Conceptualization of Circuit Design**: Engineers outline the overall function of the circuit, determining how resistors will be integrated to achieve the desired performance.

2. **Selection of Resistor Types and Values**: Based on the circuit requirements, engineers select appropriate resistor types and values, considering factors such as tolerance and power rating.

B. Drafting the Wiring Diagram

Once the initial design is established, the next step is drafting the wiring diagram:

1. **Software Tools Used**: Engineers often use specialized software tools, such as CAD (Computer-Aided Design) programs, to create precise and professional wiring diagrams. These tools offer features that streamline the design process and enhance accuracy.

2. **Standardized Symbols and Notations**: Adhering to standardized symbols and notations is crucial for ensuring that the wiring diagram is easily understood by others in the field. This consistency helps prevent misinterpretation and errors.

C. Review and Revision

After drafting the wiring diagram, it undergoes a review and revision process:

1. **Peer Review Process**: Collaborating with colleagues allows for constructive feedback, helping to identify potential issues or areas for improvement in the diagram.

2. **Testing for Accuracy and Clarity**: Engineers test the diagram for accuracy, ensuring that all connections are correctly represented and that the diagram is clear and easy to follow.

V. Finalization and Documentation

A. Finalizing the Wiring Diagram

Once the review process is complete, the wiring diagram is finalized:

1. **Formatting and Presentation**: The diagram is formatted for clarity and professionalism, ensuring that it meets industry standards for presentation.

2. **Ensuring Compliance with Standards**: Compliance with relevant industry standards is essential for ensuring that the wiring diagram is acceptable for use in professional settings.

B. Documentation and Record Keeping

Proper documentation and record-keeping practices are vital for future reference:

1. **Version Control**: Keeping track of different versions of the wiring diagram helps maintain a clear history of changes and updates.

2. **Archiving for Future Reference**: Archiving completed diagrams ensures that they are readily accessible for future projects or troubleshooting efforts.

VI. Quality Control in the Production Process

A. Importance of Quality Control

Quality control is a critical aspect of the production process, ensuring that wiring diagrams are accurate and reliable. High-quality diagrams reduce the risk of errors during circuit assembly and troubleshooting.

B. Methods of Quality Assurance

1. **Testing and Validation**: Rigorous testing and validation processes help confirm that the wiring diagram accurately represents the intended circuit design.

2. **Feedback Mechanisms**: Establishing feedback mechanisms allows engineers to learn from past projects, continuously improving the quality of future wiring diagrams.

C. Continuous Improvement Practices

Implementing continuous improvement practices fosters a culture of excellence within the engineering team. Regular training, workshops, and reviews of best practices contribute to the ongoing enhancement of the production process.

VII. Conclusion

In summary, the production process of mainstream resistor wiring diagrams involves several critical steps, from understanding resistors and their applications to drafting, reviewing, and finalizing diagrams. Accurate wiring diagrams are essential for successful circuit design and troubleshooting, ensuring that electronic devices function as intended. As technology continues to evolve, the importance of precise and well-documented wiring diagrams will only grow, paving the way for future advancements in resistor design and circuit development.

VIII. References

A. Books and Articles on Resistor Technology

B. Online Resources and Tools for Wiring Diagrams

C. Industry Standards and Guidelines

This comprehensive overview of the production process of resistor wiring diagrams highlights the importance of each step in creating effective and reliable circuit designs. By understanding and implementing these processes, engineers can contribute to the advancement of electronic technology and ensure the successful operation of countless devices.