Common Production Processes for Resistor Boxes

I. Introduction

A. Definition of Resistor Boxes

Resistor boxes are essential components in electronic circuits, designed to provide specific resistance values for various applications. They can be used for testing, calibration, and prototyping, allowing engineers and technicians to simulate different circuit conditions without the need for multiple individual resistors.

B. Importance of Resistor Boxes in Electronic Circuits

In the realm of electronics, resistors play a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. Resistor boxes enhance this functionality by offering a versatile solution that can accommodate a range of resistance values in a single unit. This versatility is particularly valuable in educational settings, laboratories, and during the development of electronic devices.

C. Overview of the Production Process

The production of resistor boxes involves several key processes, from design and prototyping to manufacturing and quality assurance. Understanding these processes is vital for ensuring that the final product meets the required specifications and performance standards.

II. Types of Resistor Boxes

A. Fixed Resistor Boxes

Fixed resistor boxes contain resistors with predetermined resistance values. They are commonly used in applications where specific resistance is required, such as in circuit testing and calibration.

B. Variable Resistor Boxes

Variable resistor boxes allow users to adjust the resistance value as needed. These are particularly useful in experimental setups where different resistance values are required for testing various circuit configurations.

C. Specialty Resistor Boxes

Specialty resistor boxes are designed for specific applications, such as high-power or precision resistors. These boxes may incorporate unique materials or designs to meet specialized requirements.

D. Applications of Different Types

Each type of resistor box serves distinct purposes across various industries, including telecommunications, automotive, and consumer electronics. Their adaptability makes them indispensable tools for engineers and technicians.

III. Materials Used in Resistor Box Production

A. Resistor Elements

The performance of a resistor box largely depends on the materials used for its resistor elements. Common materials include:

1. **Carbon Composition**: Known for their low cost and good performance, carbon composition resistors are often used in fixed resistor boxes.

2. **Metal Film**: These resistors offer better stability and precision, making them suitable for applications requiring high accuracy.

3. **Wirewound**: Wirewound resistors are ideal for high-power applications due to their ability to dissipate heat effectively.

B. Enclosure Materials

The enclosure of a resistor box protects the internal components and ensures durability. Common materials include:

1. **Plastic**: Lightweight and cost-effective, plastic enclosures are widely used for general-purpose resistor boxes.

2. **Metal**: Metal enclosures provide enhanced protection and are often used in high-performance or specialty resistor boxes.

C. Connectors and Terminals

Connectors and terminals are critical for ensuring reliable electrical connections. They must be made from conductive materials that can withstand repeated use without degradation.

IV. Common Production Processes

A. Design and Prototyping

1. Circuit Design

The production process begins with circuit design, where engineers create schematics that outline the resistor box's functionality. This stage involves selecting the appropriate resistor types and values based on the intended application.

2. Simulation and Testing

Before moving to production, simulations are conducted to predict the performance of the resistor box under various conditions. This step helps identify potential issues and allows for adjustments to be made before physical prototypes are created.

B. Component Sourcing

1. Supplier Selection

Once the design is finalized, manufacturers must source the necessary components. This involves selecting reliable suppliers who can provide high-quality materials at competitive prices.

2. Quality Control

Quality control is essential during component sourcing to ensure that all materials meet the required specifications. This step helps prevent defects in the final product.

C. Manufacturing Processes

1. Resistor Element Fabrication

The fabrication of resistor elements is a critical step in the production process. Different methods are used depending on the type of resistor:

Carbon Composition Production: This involves mixing carbon with a binding agent and forming it into the desired shape before curing it to achieve the final resistance value.

Metal Film Deposition: In this process, a thin layer of metal is deposited onto a ceramic substrate, which is then etched to create the desired resistance pattern.

Wirewound Resistor Construction: Wirewound resistors are made by winding a resistive wire around a core, which is then encapsulated to protect it from environmental factors.

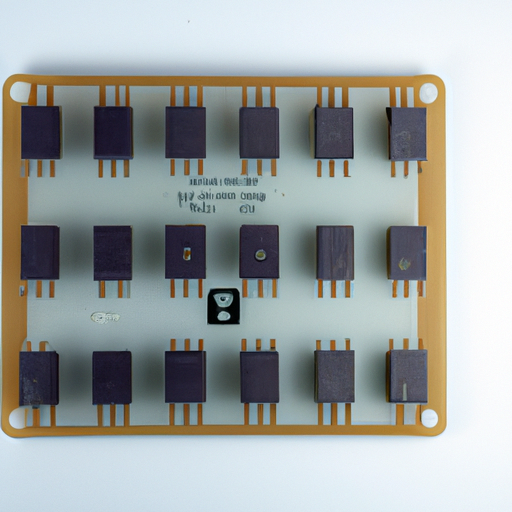

2. Assembly of Resistor Boxes

The assembly process involves several steps:

Mounting Resistors: Resistor elements are mounted onto a circuit board or directly into the enclosure, depending on the design.

Wiring and Connections: Electrical connections are made to ensure that the resistors function correctly within the circuit.

Enclosure Assembly: The enclosure is assembled to protect the internal components, ensuring durability and reliability.

D. Quality Assurance and Testing

1. Electrical Testing

Once assembled, resistor boxes undergo electrical testing to verify that they meet the specified resistance values and performance criteria.

2. Environmental Testing

Environmental testing assesses the resistor box's performance under various conditions, such as temperature and humidity, to ensure reliability in real-world applications.

3. Compliance with Standards

Manufacturers must ensure that their products comply with industry standards and regulations, which may vary by region and application.

V. Automation and Technology in Production

A. Role of Automation in Manufacturing

Automation plays a significant role in the production of resistor boxes, enhancing efficiency and reducing labor costs. Automated systems can handle repetitive tasks, such as component assembly and testing, with high precision.

B. Use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)

CAD and CAM technologies streamline the design and manufacturing processes. CAD software allows engineers to create detailed designs, while CAM systems facilitate the automated production of components based on these designs.

C. Advancements in Production Technology

Recent advancements in production technology, such as 3D printing and advanced materials, are revolutionizing the way resistor boxes are manufactured. These innovations enable greater customization and faster production times.

VI. Challenges in Resistor Box Production

A. Material Sourcing Issues

Sourcing high-quality materials can be challenging, especially in a global market where supply chain disruptions can occur. Manufacturers must develop strong relationships with suppliers to mitigate these risks.

B. Quality Control Challenges

Maintaining consistent quality across production batches is crucial. Manufacturers must implement rigorous quality control measures to identify and address defects early in the production process.

C. Environmental Regulations

Compliance with environmental regulations is becoming increasingly important. Manufacturers must adopt sustainable practices and ensure that their production processes minimize environmental impact.

D. Market Demand Fluctuations

Market demand for resistor boxes can fluctuate based on technological advancements and industry trends. Manufacturers must remain agile and responsive to changes in demand to stay competitive.

VII. Future Trends in Resistor Box Production

A. Innovations in Materials

The development of new materials, such as conductive polymers and nanomaterials, is expected to enhance the performance and versatility of resistor boxes.

B. Miniaturization and Integration

As electronic devices continue to shrink in size, there is a growing demand for smaller, more integrated resistor boxes. Manufacturers will need to adapt their production processes to meet these requirements.

C. Sustainable Manufacturing Practices

Sustainability is becoming a key focus in manufacturing. Companies are exploring eco-friendly materials and processes to reduce their environmental footprint and appeal to environmentally conscious consumers.

VIII. Conclusion

A. Summary of Key Points

Resistor boxes are vital components in electronic circuits, with various types and applications. The production process involves multiple stages, including design, component sourcing, manufacturing, and quality assurance.

B. The Importance of Efficient Production Processes

Efficient production processes are essential for ensuring that resistor boxes meet the required specifications and performance standards. Automation and advanced technologies play a crucial role in enhancing efficiency and reducing costs.

C. Future Outlook for Resistor Box Manufacturing

As the electronics industry continues to evolve, the production of resistor boxes will need to adapt to new challenges and opportunities. Innovations in materials, miniaturization, and sustainable practices will shape the future of resistor box manufacturing.

IX. References

A. Academic Journals

- Journal of Electronic Materials

- IEEE Transactions on Components, Packaging and Manufacturing Technology

B. Industry Reports

- Market Research Reports on Resistor Technologies

- Global Resistor Market Analysis

C. Manufacturer Guidelines

- Manufacturer specifications and guidelines for resistor box production

- Industry standards for electronic components

This comprehensive overview of the common production processes for resistor boxes highlights the importance of these components in electronic circuits and the intricate processes involved in their manufacturing. As technology advances, the production of resistor boxes will continue to evolve, ensuring their relevance in the ever-changing landscape of electronics.