What are the Latest Resistor Resistance Values and Equipment Component Purchasing Models?

I. Introduction

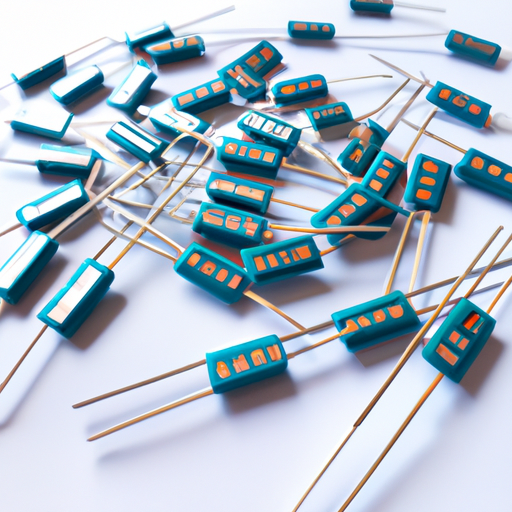

Resistors are fundamental components in electronic circuits, serving the crucial role of controlling current flow and voltage levels. Their importance cannot be overstated, as they are integral to the functionality of virtually all electronic devices, from simple gadgets to complex machinery. The resistance values of these components are vital in determining how they perform in various applications, influencing everything from power consumption to signal integrity. This article aims to explore the latest resistor resistance values and the evolving purchasing models for electronic components, providing insights into how these factors impact the electronics industry.

II. Understanding Resistor Resistance Values

A. Explanation of Resistance and Its Measurement

Resistance, measured in ohms (Ω), quantifies how much a resistor opposes the flow of electric current. The relationship between voltage (V), current (I), and resistance (R) is defined by Ohm's Law, expressed as V = I × R. Understanding this relationship is essential for designing circuits that function correctly and efficiently.

B. Types of Resistors and Their Resistance Values

1. **Fixed Resistors**: These resistors have a constant resistance value and are the most commonly used type. They come in various resistance values, typically categorized into standard series such as E12, E24, E48, E96, and E192, which represent different levels of precision.

2. **Variable Resistors**: These include potentiometers and rheostats, allowing users to adjust resistance values as needed. They are often used in applications requiring user input, such as volume controls in audio equipment.

3. **Specialty Resistors**: This category includes thermistors, photoresistors, and other types designed for specific applications. For instance, thermistors change resistance with temperature, making them ideal for temperature sensing.

C. Standard Resistance Values and the E-Series

The E-series provides a standardized set of resistance values that manufacturers adhere to, ensuring compatibility and availability. The E12 series includes 12 values per decade, while the E24 series offers 24 values, and so on. These series help engineers select appropriate resistors for their designs, ensuring they meet the required specifications.

D. Recent Trends in Resistance Values

1. **Miniaturization and Precision Resistors**: As electronic devices become smaller and more complex, there is a growing demand for miniaturized and precision resistors. These components are designed to occupy less space while maintaining high accuracy, making them ideal for modern applications.

2. **High-Power and High-Precision Applications**: Industries such as automotive and aerospace require resistors that can handle high power and provide precise measurements. Recent advancements have led to the development of resistors that can withstand extreme conditions while delivering reliable performance.

3. **Emerging Materials and Technologies**: The use of new materials, such as carbon nanotubes and graphene, is influencing the development of resistors. These materials offer unique properties that can enhance performance, such as lower resistance values and improved thermal stability.

III. Factors Influencing Resistor Selection

A. Application Requirements

When selecting resistors, engineers must consider several application-specific factors:

1. **Power Rating**: The power rating indicates how much power a resistor can dissipate without failing. Choosing a resistor with an appropriate power rating is crucial to prevent overheating and ensure reliability.

2. **Tolerance and Temperature Coefficient**: Tolerance refers to the allowable deviation from the specified resistance value, while the temperature coefficient indicates how resistance changes with temperature. Both factors are essential for ensuring that the resistor performs as expected in varying conditions.

3. **Environmental Considerations**: Factors such as humidity, temperature, and exposure to chemicals can affect resistor performance. Selecting components that can withstand the intended environment is vital for long-term reliability.

B. Cost Considerations

Cost is always a factor in component selection. Engineers must balance performance requirements with budget constraints, often opting for resistors that provide the best value without compromising quality.

C. Availability and Lead Times

The availability of specific resistor types and their lead times can significantly impact project timelines. Engineers must consider these factors when planning their designs to avoid delays.

D. Manufacturer Reputation and Reliability

Choosing reputable manufacturers can ensure that the resistors meet quality standards and perform reliably. Researching manufacturer backgrounds and customer reviews can help engineers make informed decisions.

IV. Equipment Component Purchasing Models

A. Overview of Purchasing Models in the Electronics Industry

The purchasing landscape for electronic components has evolved significantly, with various models available to meet the needs of manufacturers and engineers.

B. Traditional Purchasing Methods

1. **Direct Purchasing from Manufacturers**: This method involves buying components directly from the manufacturer, often resulting in lower costs but requiring larger minimum order quantities.

2. **Distributors and Wholesalers**: Distributors provide a wide range of components from various manufacturers, making it easier for engineers to source parts without dealing with multiple suppliers.

C. Modern Purchasing Models

1. **Online Marketplaces and E-Commerce Platforms**: The rise of online marketplaces has transformed how engineers purchase components. Platforms like Digi-Key, Mouser, and Alibaba offer vast selections and competitive pricing, allowing for quick and easy ordering.

2. **Just-in-Time (JIT) Inventory Systems**: JIT systems enable manufacturers to order components as needed, reducing inventory costs and minimizing waste. This model requires strong relationships with suppliers to ensure timely delivery.

3. **Subscription-Based Models for Regular Component Supply**: Some companies offer subscription services that provide regular shipments of components, ensuring that engineers have the parts they need without the hassle of reordering.

D. Comparison of Purchasing Models

1. **Advantages and Disadvantages of Each Model**: Traditional methods may offer lower costs but can involve longer lead times. Modern models provide convenience and flexibility but may come with higher prices.

2. **Impact on Cost, Lead Time, and Inventory Management**: The choice of purchasing model can significantly affect project costs, timelines, and inventory management strategies. Engineers must carefully evaluate their options to find the best fit for their needs.

V. The Role of Technology in Resistor and Component Purchasing

A. Digital Tools and Platforms for Component Selection

Advancements in technology have led to the development of digital tools that simplify component selection. Online calculators and databases allow engineers to quickly find suitable resistors based on their specifications.

B. The Impact of AI and Machine Learning on Purchasing Decisions

AI and machine learning are increasingly being used to analyze purchasing patterns and predict future needs. These technologies can help companies optimize their inventory and reduce costs.

C. Supply Chain Management Software and Its Importance

Effective supply chain management is crucial for ensuring timely delivery of components. Software solutions can help companies track orders, manage inventory, and streamline purchasing processes.

D. Future Trends in Technology and Purchasing Models

As technology continues to evolve, we can expect further innovations in purchasing models and component selection. The integration of IoT and blockchain technology may enhance transparency and efficiency in the supply chain.

VI. Case Studies

A. Examples of Companies Successfully Implementing Modern Purchasing Models

Several companies have successfully adopted modern purchasing models to improve their operations. For instance, a leading automotive manufacturer implemented a JIT inventory system, resulting in significant cost savings and reduced lead times.

B. Analysis of How Resistor Selection Impacted Product Performance in Real-World Applications

In another case, a consumer electronics company faced performance issues due to improper resistor selection. By reevaluating their component choices and opting for higher precision resistors, they improved product reliability and customer satisfaction.

VII. Conclusion

In summary, understanding the latest resistor resistance values and the various purchasing models available is essential for engineers and manufacturers in the electronics industry. Staying updated with trends in resistor technology and component sourcing can lead to better product performance and more efficient operations. As the industry continues to evolve, embracing new technologies and purchasing strategies will be crucial for success in an increasingly competitive landscape.

VIII. References

A comprehensive list of academic papers, articles, and resources for further reading, along with industry standards and guidelines related to resistors and electronic components, can be found in the references section. This information will provide additional insights and support for those looking to deepen their understanding of resistor technology and purchasing models.